1974 - Barge

| Year | 1974 |

| Vessel | Barge |

| Location | Duwamish Waterway, USA |

| Cargo type | Package |

| Chemicals | POLYCHLORINATED BIPHENYLS |

Summary

On September 13, 1974, an electrical transformer was dropped on the quay while being loaded by a crane onto a barge in the Duwamish Waterway, Seattle, which is a tidal shipping channel tributary to Puget Sound, U.S.A. The transformer was packed in a wooden box and bolted to a 4" x 4" pallet. When hoisting the box, one or both of the planks of the pallet broke at the point where they were bolted. The transformer fell to the quay and was punctured. Most of the one cubic metres of polychlorinated biphenyl (PCB) used as cooling liquid in the transformer leaked onto the quay and into the adjacent Duwamish Waterway.

The Duwamish Waterway is a major anadromous fish run in the area where fish migrate up the river to spawn. The hazard of the spill was not realized until four days after the event when laboratory personnel and divers arrived and examined the place. The divers could observe pools of PCB on the bottom of the 8 metre deep waterway.

Narrative

On September 13, 1974, an electrical transformer was dropped on the quay while being loaded by a crane onto a barge in the Duwamish Waterway, Seattle, which is a tidal shipping channel tributary to Puget Sound, U.S.A. The transformer was packed in a wooden box and bolted to a 4" x 4" pallet. When hoisting the box, one or both of the planks of the pallet broke at the point where they were bolted. The transformer fell to the quay and was punctured. Most of the one cubic metres of polychlorinated biphenyl (PCB) used as cooling liquid in the transformer leaked onto the quay and into the adjacent Duwamish Waterway.

The Duwamish Waterway is a major anadromous fish run in the area where fish migrate up the river to spawn. The hazard of the spill was not realized until four days after the event when laboratory personnel and divers arrived and examined the place. The divers could observe pools of PCB on the bottom of the 8 metre deep waterway.

Resume

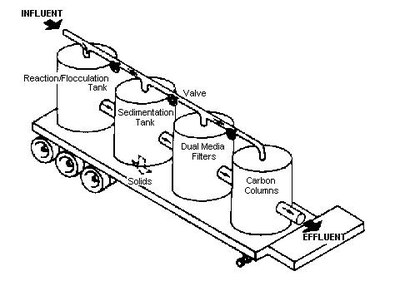

On October 9, a fifty ton special chemical treatment unit was brought in. This equipment had been previously used extensively by the EPA's Environmental Emergency Response Unit. The area was first dredged using a hand-held suction device manipulated by divers with a pump and storage tank on board a barge (Figure 1). The divers recovered 30 per cent of the material by dredging the bottom mud, up to a depth of 0.5 metres. During the dredging operation, the river level depth was checked by means of a fathometer readings over a cross section of the spill area. The depth checks were made aboard a Coast Guard cutter that was in attendance throughout the operation. The perimeter of the contaminated river area was physically cordoned off by a bubble air curtain established by pumping air through a perforated fire hose lying on the bottom around the area. The purpose of the bubble screen was two-fold: 1) to protect migrating fish; and 2) to prevent the PCB from spreading.

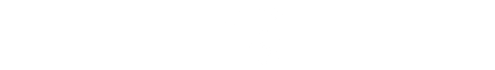

The contaminated mud was then passed through the physical/chemical treatment unit which is used for treating water contaminated with hazardous materials. The unit is a mobile system mounted on a tow-trailer. It consists of tanks for flocculation/sedimentation, filtration and carbon adsorption (Figure 2). Contaminated water is pumped into a settling tank where flocculation and sedimentation occur. The clarified liquid is drawn off and is then passed through mixed media filters and finally through carbon adsorption columns. The sludge is removed from the sedimentation tank and stored for ultimate disposal. Each step can be by-passed. 2,300m3 of contaminated slurry was handled by this unit and purified through settling and filtering using Nalco 634, a polyelectrolyte. This agent was chosen after tests with several different agents had been carried out. 215 drums of PCB contaminated mud was collected and later transferred to a special site for final disposal.