1982 - Sam Houston

| Year | 1982 |

| Vessel | Sam Houston |

| Location | Off New Orleans, USA |

| Cargo type | Package |

| Chemicals | DIETHYLENETRIAMINE , HEXACHLOROCYCLOPENTADIENE , n-BUTYL ACRYLATE inhibited , PETROLEUM DISTILLATES (flashed feed stocks) , TRIETHYLENETETRAMINE |

Summary

On March 7, 1982, while underway from New Orleans to ports on the East Coast of the U.S.A., the chief engineer noticed a strong, unidentifiable odour near the exhaust of C cell aboard the LASH vessel S/S Sam Houston.

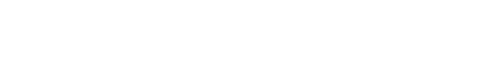

Lighter Aboard Ships (LASH) are large, low ships with no sheer and very little superstructure. They carry watertight containers. The containers are non-propelled barges that are loaded and discharged from the vessel into the water using an onboard crane, allowing them to be used independently of the mother ship. Although the barges are watertight, they can be ventilated by forced air from the mother ship via exhaust vents in both ends. In this particular case, the LASH vessel carried 89 stacked containers.

Narrative

On March 7, 1982, while underway from New Orleans to ports on the East Coast of the U.S.A., the chief engineer noticed a strong, unidentifiable odour near the exhaust of C cell aboard the LASH vessel S/S Sam Houston.

Lighter Aboard Ships (LASH) are large, low ships with no sheer and very little superstructure. They carry watertight containers. The containers are non-propelled barges that are loaded and discharged from the vessel into the water using an onboard crane, allowing them to be used independently of the mother ship. Although the barges are watertight, they can be ventilated by forced air from the mother ship via exhaust vents in both ends. In this particular case, the LASH vessel carried 89 stacked containers.

Resume

The chief engineer and chief officer determined that the odour probably emanated from either barge 3C or 3D (Figure 1). The officers checked the barge sequence list, stowage plan and dangerous goods manifest and determined that each of these barges contained numerous 208 litre drums of hazardous chemicals. Contents of the suspected leaking barges on the vessel were:

Barge 3C

Diethylenetriamine 26 drums

Triethylenetetramine 25 drums

Trimethylenediamine 3 drums

Alkyl amines and Polyamines 49 drums

Butyl acrylate 160 drums

Barge 3D

Hexachlorocyclopentadiene (C56) 127 drums

Petroleum distillates 30 drums

The stacked loading of the barges prevented visual inspection of the contents which could determine if the odour was caused by any leakage in the cargo.

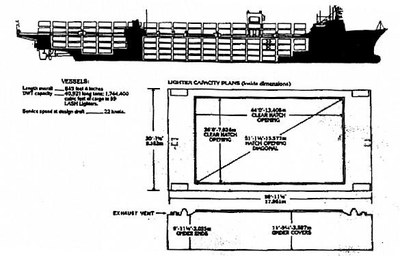

The owners of the vessel were informed by the chief officer. A decision was made to detour to Newport News, Virginia to discharge the problem barge(s). The hold containing the barges was secured and ventilated en route to the Virginia destination (Figure 2). On March 9, the owners of the vessel informed the Marine Safety Office (MSO) of the U.S. Coast Guard at Hampton Roads about the possibility of a leaking substance on the vessel as indicated by the presence of a pungent smell. The Coast Guard pollution report indicated that the suspect chemical was hexachlorocyclopentadiene, also know as C56 (part of cargo in cell 3D). This chemical is an intermediate used in the manufacture of pesticides. The manufacturer of C56 was notified.

The local shipping agent informed the (MSO) that the vessel would proceed to Newport News anchorage to discharge the barge for transport to shore and that the company would provide a specific proposal for cleanup the following day.

A meeting of government and industry representatives was convened to discuss equipment that could be used to analyze the exhaust vapours and determine the cause of the odour and the chemical properties of each of the suspect chemicals to determine if any identifying characteristics matched the odour description. It became apparent that no equipment was available to identify positively the chemical responsible for the odour. However, an organoleptic (smell) test by the manufacturers could determine if the odour was from C56. It was agreed that representatives from the manufacturer and from the vessel owners as well as an independent marine chemist would board the vessel on March 10 to carry out the organoleptic test and to test for the presence of an explosive atmosphere and oxygen levels in the gases being vented. Plans were also made for a response team from the Coast Guard to also board the vessel. Explosive meter reading did not indicate an explosive atmosphere whilst the evaluation from the manufacturer of C56 in barge 3D was that the product was not the cause of the odour. His past experience led him to shift his suspicion to butyl acrylate in barge 3C. However, because of the flammability of the other cargo, it was necessary to determine the identity of the chemicals causing the odour.

Before boarding of the various representatives, the following conclusions were drawn based on the physical and chemical data concerning the chemicals listed in the manifest:

1. Virtually all the chemicals have sufficient vapour pressures to cause a detectable odour. Even though the odour thresholds were not readily available, butyl acrylate, hexachlorocylopentadiene (C56), and the various alkyl amines produce strong odour sensations that could be described as "pungent".

2. With the exception of C56, all of the chemicals are flammable and have the potential in a closed environment and at the temperatures found in container barges to produce an explosive environment.

3. Virtually all of the chemicals can be classified as irritants; additionally, C56 is a highly toxic substance with a threshold limit value (TLV) of 0.01ppm.

4. If ignited, the chemicals in the barge would produce highly dangerous and noxious fumes.

5. Commonly available portable vapour detection instruments could not detect and distinguish all of these chemicals at their TLVs against a background of diesel fuel and could not distinguish mixtures of these chemicals under field conditions.

6. Although these chemicals have distinctive odours, the independent characteristics of the odours are not readily describable to shipboard personnel, government response personnel and others who do not have a background in the handling of these chemicals. Consequently, odour information provided by the crew of the Sam Houston would have been of limited value in helping to determine which chemical or chemicals had leaked into the barge.

7. Organoleptic testing by the manufacturer could be viewed as a valid means of identification since a manufacturer is capable of recognizing the smell of a chemical with which he works on a daily basis. However, the use of this test as an analytical method, although reliable, normally would not have been considered within prudent safety limits because documentation showed the odour threshold and TLV to be very close, i.e. by the time the odour was noticeable, exposure limits for C56 are close to being exceeded. In this case, the manufacturer thought it was safe to conduct the test. Otherwise it would have been recommended for the test to be carried out.

The vessels owners requested permission for barge 3C to be towed to shore in the morning. Pending a visit to the vessel by the relevant authorities to ascertain that there was no leakage, permission was granted to offload the barge. However, the City of Newport News denied permission for the barge to dock at a facility within the city limits until an independent industrial hygienist confirmed the source of the odour and confirmed the exact nature of the hazards.

Following a meeting with the shippers, response personnel, scientific advisers, Coast Guard personnel and state and city officers, it was decided that the city find an isolated controlled-access site and that a safety zone and cleanup plans be established before admitting the barge into the city's jurisdiction. These plans were prepared with consultations with the manufacturer of butyl acrylate. Subsequently, the barge 3C was towed to an unused pier in an isolated section of the waterfront industrial park. No facilities or traffic routes were within 1/2km where the barge was to dock.

The barge hatches were removed on the morning of March 12. Fire-fighting equipment and personnel in SCBA (self-contained breathing apparatus) were stationed at the site and placed on standby. On hand were representatives from the vessel, the Coast Guard, the water control agency, the manufacturer, city officials and response personnel.

Technicians from the manufacturer boarded the vessel wearing organic vapour masks.

They measured an oxygen level of 21% using an oxygen meter. Reading of an explosion meter showed 0%. None of the drums showed signs of leaking. However, the tops of many drums showed signs of bulging. Some concern was expressed to ensure that this condition was not the result of overpacking and the drums would remain in tact should the shipment continue to its scheduled destination which was Bombay, India.

Following consultation with the facility that packaged the butyl acrylate in drums, it was explained that the drum lids were concave or convex before loading. Also, when properly packed, drums loaded with butyl acrylate should weigh about 200kgs. This information indicated that the bulging tops were not necessarily a sign that the drums were overpacked and therefore incapable of withstanding shipment. On-site personnel weighed one of the drums that displayed the most prominent bulging lid. This was found to be within the safe limits. On opening the bung cap in the lid, about 4cm of head space was found which, according to the manufacturers of the product, was sufficient for a safe transit through tropical temperatures to Bombay, India.

On the afternoon of March 12, permission was granted to the vessel owners to re-pack the barge 3C and send it on to its destination.

The first explanation given for the persistence of the odour, assuming that no spill had occurred, was that residue from filling the drums remained on the outside, providing a source of vapours. However, it was noted that it would be unlikely that drums in such a contaminated state would be shipped or accepted for shipment.

A plausible explanation offered later by an expert from the manufacturer of butyl acrylate was that vapourized molecules could pass through the spaces around the threads on the bung caps. Although the caps offered reliable protection from any liquid seepage, experience in storing drums at the plant had shown that a relatively small difference in temperature (night to day) causes minuscule exchange between the vapours in the head space inside the drum and the external air. This process could cause a continuous stream of very small amounts of vapours to be emitted from the drums which would explain why butyl acrylate odours persisted in the barge, especially when one considers that the odour threshold of the substance is only 0.39ppb.