1988 - Anna Broere

| Year | 1988 |

| Vessel | Anna Broere |

| Location | Off Ijmuiden, Netherlands |

| Cargo type | Bulk |

| Chemicals | ACRYLONITRILE inhibited |

Summary

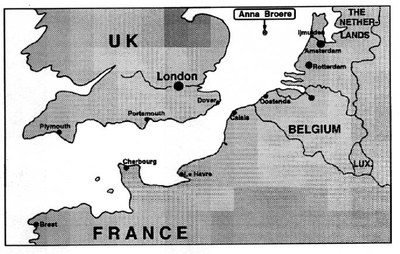

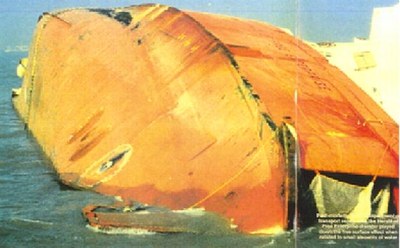

The Dutch tanker "Anna Broere", of 1500 grt, on her way from Rotterdam to England, collided with the Swedish container ship Atlantic Compass on Friday, May 27 1988, The Anna Broere sank due to the damage sustained to the hull at the starboard side, 60 miles west of Ijmuiden, the Netherlands (Figure 1).

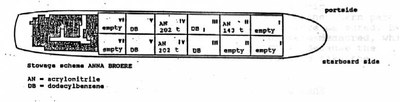

The Anna Broere carried 547 tons of acrylonitrile and 500 tons of dodecylbenzene (a linear alkyl benzene).

Acrylonitrile is toxic in both liquid and vapour and can be lethal in high concentrations. It has also been found to be carcinogenic over long exposure periods. However, no permanent damage is considered to be caused by short-term exposures once a person recovers from the acute exposure.

Because of acrylonitrile's tendency for polymerising during transport and storage, an inhibiting agent is added to the liquid which temporarily prevents this reaction. If uninhibited, runaway polymerisation occurs and the heat liberated during the process may cause the chemical to explode, particularly if the liquid is contained.

If spilled into the marine environment, acrylonitrile will dissolve and evaporate.

Dodecylbenzene is a lighter than sea-water liquid having a solubility of 0.19% and a flash point of 133ºC. Its LC50 is >1000mg/l.

Narrative

The Dutch tanker "Anna Broere", of 1500 grt, on her way from Rotterdam to England, collided with the Swedish container ship Atlantic Compass on Friday, May 27 1988, The Anna Broere sank due to the damage sustained to the hull at the starboard side, 60 miles west of Ijmuiden, the Netherlands (Figure 1).

The Anna Broere carried 547 tons of acrylonitrile and 500 tons of dodecylbenzene (a linear alkyl benzene).

Acrylonitrile is toxic in both liquid and vapour and can be lethal in high concentrations. It has also been found to be carcinogenic over long exposure periods. However, no permanent damage is considered to be caused by short-term exposures once a person recovers from the acute exposure.

Because of acrylonitrile's tendency for polymerising during transport and storage, an inhibiting agent is added to the liquid which temporarily prevents this reaction. If uninhibited, runaway polymerisation occurs and the heat liberated during the process may cause the chemical to explode, particularly if the liquid is contained.

If spilled into the marine environment, acrylonitrile will dissolve and evaporate.

Dodecylbenzene is a lighter than sea-water liquid having a solubility of 0.19% and a flash point of 133ºC. Its LC50 is >1000mg/l.

Resume

On being notified of the collision, the Netherlands Coastguard Centre started SAR operations while the North Sea Directorate was responsible for the hazard evaluation of the vessel's cargo. From a crew of 11, 10 men were taken onboard the Atlantic Compass: the second mate was missing. The second engineer, who was badly injured in the fire in the engine room together with the cook, were later transferred by helicopter to a hospital.

An exclusion zone of 10km radius was established for maritime traffic and 300 metres for air traffic. This was supervised by the Dutch Royal Navy.

Using the POLREP system, countries belonging to the regional agreement operating within the North Sea were informed. Shipping and air traffic in the area were also informed.

The next day, air measurements were taken 40 miles downwind from a vessel whilst another vessel placed buoys to mark the area where the wreck was located and to assist with supervising the area. No presence of acrylonitrile vapour in the air was recorded. A vessel with a diving team also went to the scene to assess the state of the Anna Broere which lay on her starboard side with her bow approximately 15 metres above the sea surface.

A decision-making team met on May 28 and after having the stowage plan of the ship described by the ship owner (Figure 2), it was considered possible that tank 4 on the starboard side containing acrylonitrile would leak. The results of the diving survey showed clearly that the starboard side was heavily damaged and tanks 5 and 3 were leaking dodecylbenzene, but it was not possible to determine if tank 4, containing the acrylonitrile, was in fact leaking. Following another diving survey on May 30, it was decided to salvage the vessel.

Following a call for tenders, Smit Tak was assigned the job and operations started on June 1. It was estimated that the operation would last 10 days. The salvage operation was to flip over the vessel and lift it using a floating sheerleg. However, due to bad weather, only the cable could be connected and the operation then suspended.

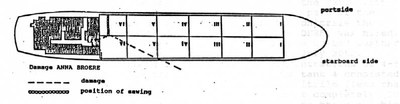

On June 16, another attempt took place, but in the righting and lifting attempt, two cables broke and the ship sank. It was then decided to saw the ship in two parts (Figure 3): the stern part with tank 4 (leaking acrylonitrile) from the rest of the vessel; and to tranship the cargo from the leaking tank.

On June 30, the Anna Broere was turned over after which the sawing operation began. Continual air monitoring took place during the operation and the crew of the floating sheerleg withdrew immediately after the turn-over operation because concentrations of acrylonitrile in the air were over the MAC value of 4ppm. The next day, the ship was sawed into two parts. Concentrations of acrylonitrile in the water column near the ship were 0.3ppm at 0.1m depth and 10 - 35ppm at 1 - 10m depth. (The LC50 values for acrylonitrile reported in the literature varied from 0.05 to 6ppm).

On July 2, preparations were made to lift the stern part of the ship. No concentrations of acrylonitrile were measured in the air but on July 5, air concentrations of 4 - 6ppm were measured which made it unsafe for salvage personnel to work on the floating sheerleg. Due to inclement of weather, the salvage operation was suspended.

On July 13, it was decided to first tranship the cargo from tank 4 in an underwater operation to another chemical carrier brought in for the purpose and then to lift the stern part of the ship. Due to bad weather conditions, this operation was delayed until July 20. During the tranship, 4 to 5ppm of acrylonitrile was measured in the air. The cargo transhipped from tank 4 consisted mostly of sea water (less than 2% of acrylonitrile content was found) indicating that most of the chemical had been lost.

Lifting of the stern part of the ship was again delayed until August 5 when it was placed on a barge and the remaining acrylonitrile transferred to the chemical tanker. On August 8, the astern part of the ship was placed on the barge. On August 10, the Anna Broere entered the harbour of Rotterdam.

The ship was cleared and given to a scrapping contractor in Rotterdam. The sea water-contaminated-acrylonitrile was given to a company for disposal whilst the remaining cargo of acrylonitrile was sold to a company for recycling. Dodecylbenzene was also sold and recycled.

Twenty-five days of actual salvage work was carried out from a total of 73 days. Work was restricted to those days when salvage work could be carried out (winds below 5 Beaufort and sea state below 1.7m).

As a result of the damaged tanks, it was estimated that about 200 tons of acrylonitrile and 118 tons of dodecylbenzene were lost. Because of the low rate of loss (calculated to be 0.04kg/sec), the total affected area was judged to be small in comparison to acute effects from a potential instantaneous release of acrylonitrile. In fact, only the immediate surroundings of the ship (100 - 200 metres) were affected from the start to the end of the operation. Furthermore, no mortality of marine organisms was observed.

Adverse effects were however found when algae laboratory tests were carried out with water samples taken a distance away from the ship. However, due to the "ready biodegradability" of acrylonitrile, the material was considered to break down within a few weeks.